Set Screw Pillow Blocks Standard Duty

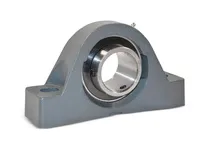

Pillow block bearings are a type of mounted bearing. They consist of a housing (a mounted block) and an insert bearing that is self-aligning. The housing, which is perpendicular to the shaft, features bolt holes that allow it to be secured to a foundation which runs parallel to the running shaft. Pillow block bearings function as support for rotating shafts and couplings in mechanical power transmission systems. This type of mounted bearing is quite versatile. It is suitable for a wide range of applications including rolling mills, ventilation systems, paper machines, conveyor belt rollers, and long shafts connecting motors and industrial gearboxes.

Take note that while the terms pillow block bearings and plummer blocks are sometimes used interchangeably, they are actually not the same. These two types of mounted bearings are used in different applications. Pillow block bearings are typically used for lightweight applications while plummer blocks are designed for high power, heavier load applications.

Pillow block bearings are available in a variety of types based on their housing construction – solid and split types – and the type of bearing used – plain, ball, roller (tapered, spherical, and needle roller bearings), and hydrodynamic bearings. These bearings can also be further categorized based on the shaft securing method used. Pillow block bearings that feature a set screw pillow blocks locking system use screws to secure the inner ring to the shaft. This type of shaft locking mechanism is easy to use and does not require a collar. In addition, they are suitable for reversing direction applications.

Click a brand image to see more

Dodge

Browning

Sealmaster

PTI

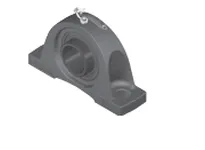

Dodge

-65° set screw locking system offers optimum balance between locking force and inner ring stress

– Precision-hardened and honed inner and outer rings with wide inner ring design

– Grade 10 balls held in place by stronger, more flexible cage

– Simple and effective anti-rotation device

– Features patented DualGuard seal; LL Lo Torque Labyrinth seals optional

– Plus or minus 2° static misalignment

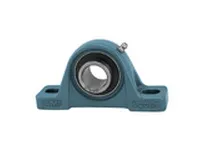

Browning

– Zone-hardened inner race results in improved lock reliability

– Semi-solid cast iron base provides excellent mounting foundation

– Set screw locking; 120° spaced, balanced three-point contact minimizes inner ring distortion vibration

– Positive contact molded nitrile rubber contact seal

– Anti-rotation rivet prevents outer ring creep, or rotation, within the housing

Sealmaster

– Black oxide outer ring is 20 to 30% wider than industry standard outer rings, resulting in increased grease capacity

– Zone hardened inner race results in improved lock reliability

– Unique land riding retainer provides superior pocket clearance

– Sealmaster exclusive locking pin and dimple system provides a direct lubricant path into the bearing cavity & ball path and prevents outer ring rotation

– Standard felt seal provides a tight labyrinth seal

– Optional single lip contact seal designed to balance drag and protection in wet and dry environments

PTI

– Cast Iron Housing

– Set Screw Lock

– High Center Height

– Metric and Inch Bores

– Solid Base Optional